- Have any question?

- +91 91674 64824

- +91 22665 95366

- export@girishmetal.com

Difference between Bright Bar and Black Bar

Page Contents

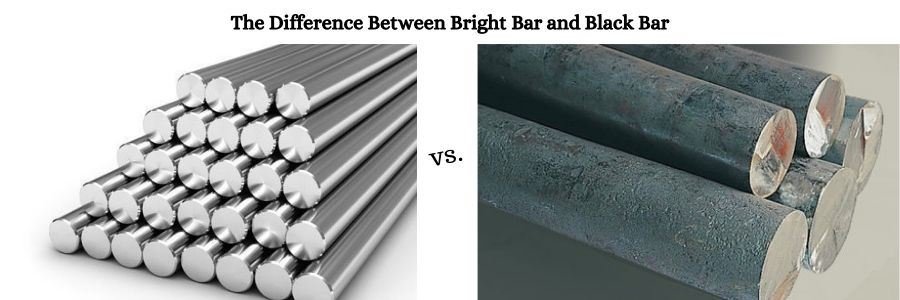

The Difference Between Bright Bar and Black Bar

Stainless Steel Bars are commonly used in industry due to their increased strength and formability. The two most frequent varieties of steel bars created and used are Stainless Steel Bright Bars and Stainless Steel Black Bars. Girish Metal India is a leading Stainless Steel Bright Bars and Stainless Steel Black Bars Manufacturer and Supplier in India. Many people wonder what the distinctions are between the two. To respond to those queries, we can remark that there are some basic variations in the milling processes for these metals. However, there isn’t much of a difference when it comes to product specifications or the quality of these metals. They can be shaped to produce outcomes by altering their strength, formability, and other qualities.

SS Bright Bar:

Bright bars are steel or metal bars that have undergone one or more cold finishing processes. The methods described below are known as Cold Finish processes or the end products are known as cold finished because no or very little heat is applied during the whole process of transforming them from hot-rolled bars (also known as black bars) to cold-finished bars or Bright Steel Bars. Bright bars are stainless steel bars with a bright finish. These bright bars are geometrically exact in terms of form and have a tight dimension tolerance. The Stainless Steel Bright Bars have a smooth and bright surface finish. As a result, it seems to be light. Stainless Steel Bright Bars can be used in a variety of ways. Stainless steel bright bars, especially round bright bars, are in great demand for a variety of fastener applications. Bolts, nuts, pins, and rivets are among the fastening items available. These fasteners can range in size from micro to mega depending on the application and end usage or needs. The ASTM A276 Stainless Steel Bright Bars division manufactures and exports cold finished bright bars in a variety of shapes and sizes, including round, hexagonal, square, and flat. Bright bars are available in diameters ranging from 3 mm to 600 mm.

Most Selling Grades of SS Bright Bar

- Stainless Steel 440C Bright Bars

- Stainless Steel 304 Bright Bar

- Stainless Steel 304L Bright Bar

- Stainless Steel 303 Bright Bars

SS Black Bar:

Black bars are made using a ‘rolling process,’ in which steel is pushed through many rolls while raw materials such as billets, blooms, and other raw materials are heated to roughly 1200 C (about 2100 F), which is higher than steel’s recrystallization temperature. Steel may be easily shaped into any desired shape and produced in considerably bigger proportions at this temperature range. Girish Metal India is a prominent manufacturer and supplier of Stainless Steel Black Bars in India. Because there are no further reheating passes required for precision while forming black bars, the procedure is usually completed quickly. Because the bar shrinks slightly after cooling, this process does not allow for exact control of its size and form. This is also why black bars are far less expensive than bright bars. Stainless Steel Black Bars come in a variety of grades that are used in various industries. ASTM A276 SS Black Polish Bars are used because of their strength and resistance to corrosion. SS 904L DIN 1.4539 Black Round Bars come in diameters ranging from 4mm to 500mm, with hex and square bars ranging from 18mm to 57mm. The length of the bars ranges from 1 to 6 meters.

Most Selling Grades of SS Black Bar

- Stainless Steel 304 Black Bar

- Stainless Steel 304L Black Bar

- Stainless Steel 440C Black Bars

- Stainless Steel 303 Black Bar

Related Stainless Steel Products

- Stainless Steel Round Bars

- Stainless Steel Bright Bars

- Stainless Steel Square bar

- Stainless Steel Black Bars

- Stainless Steel Hex bar

- Stainless Steel Flat bar

- SS Sheets/ SS Plates/ Ss Coils

- Stainless Steel Pipes and Tubes

- Stainless Steel Pipe Fittings

- Stainless Steel Flanges